Stressguard ™

A clever investment for serenity

There are many situations at sea, for any ship, platform or marine structure in general, where severe damages could have been avoided provided the officers on duty have had all necessary information and assistance tools to help them make the right decision. Important Information on utilization of the structure in critical areas and estimates of ideal loading conditions implies safer operations of the structure, by for instance optimizing the heading and forward speed of a ship.

Calculation and diagnosis tools have already been developed by Principia for marine structures such as ships, platforms, jackets, etc. and there are measurement and data acquisition systems already available on the market, using proven technologies.

PRINCIPIA is developing a Structure Integrity Management system, STRESSGUARD@SEA®, dedicated to ships and marine structures.

Its core consists in an application merging data recorded on board (sailing and /or exploitation data, and on-line recordings of stresses, accelerations, motions etc.) and results of calculation tools already developed by Principia. Measured values are automatically compared to theoretical results and/or are used to update the input of those calculations, in order to give at any time an objective view on the utilization of the structure and the potential consequences of failure. The system submits optimized load or exploitation cases to avoid critical situation for the structure, in the short and long term.

The basic module, or ‘Master Module’, is a system dedicated to fatigue and global integrity: On board Integrity calculations, local stress calculations and fatigue updates.

The architecture of the system is designed to ensure that extensions to the program can be easily incorporated in the future, ie.:

Module 1: ice impact detection, update of integrity calculation (on-board) for speed optimization (vessels sailing in Arctic conditions) and integrity survey (non-sailing structures such as high sea platforms, harbour facilities etc.),

Module 2: assistance decision tool for repair strategy (cost and useful life optimization) based on fatigue and integrity calculations (Master Module), and corrosion surveys and analysis,

Module 3: crack detection – dedicated system in case high local stresses are detected by the Master Module, based on acoustic emission detection, crack propagation calculation. Survey, repair and modification studies to be offered as services,

Module 4: decision assistance tool in case of sea damage to suggest optimized loading cases, optimized sailing speed and heading based on integrity and stability calculations.

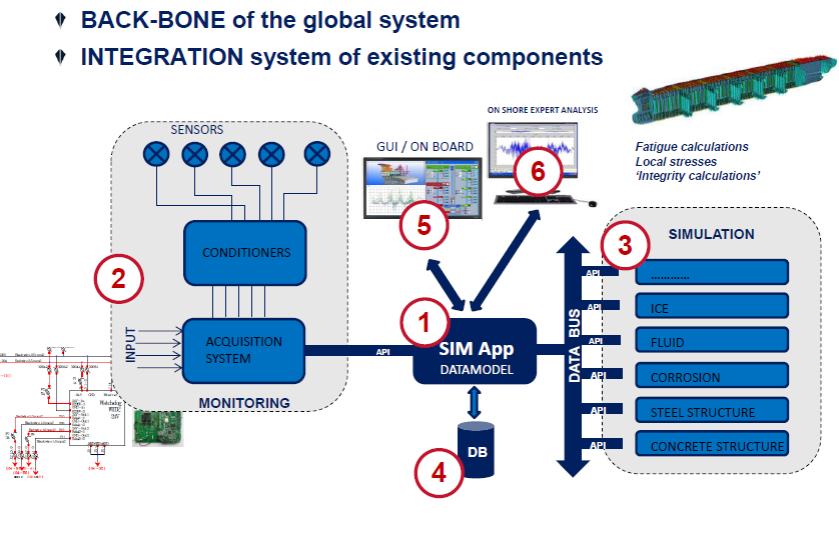

The core of the system (1) consists in developing an application that:

- Logs data recorded from on-board measurement systems, already existing or dedicated (2)

- Uses these measurements to feed calculation models selected in a ‘tool box’ (3)

- Stores results in a data base (4)

- Displays relevant information on-board (5)

Sends data on-shore for deeper analysis if/when necessary (6)